- Home

-

Bucket Elevator

More

NE series chain

NE series chain bucket elevator is the developed product which is introduction of similar foreign advanced technology, is currently more advanced kind of vertical lifting machine, has been widely used to handle a variety of bulk materials, such as ore, coal, cement clinker, grain, fertilizer and so on. In industrial countries, this type of bucket elevator is very wide application. Due to its high efficiency and energy saving, it has become an alternative choice for HL and TH type chain bucket elevator. There are 11 models of NE series chain bucket elevator: NE15, NE30, NE50, NE100, NE150, NE200, NE300, NE400, NE500, NE600, NE800, chain speed ≤40m / min. Furthermore, the company also design extended model its capacity is between the above model based on user requirements.

More

NSE series chain

NSE series of high-speed chain bucket elevator is a new type vertical lifting machine, which is the developed product of introducing similar foreign advanced technology. It is suitable for lifting powder and small granular material, such as cement, coal, other small granular material after crushed and so on. It is widely used in building materials, metallurgy, coal, electricity industry etc.

There are more than 10 basic models of NSE series chain bucket elevator: NSE100 to NSE1900, lift capacity from 100m3 / h to 1900m3 / h. Choose different lifting speeds and different bucket shapes ( D, A, L type) based on the lifting materials for each model, the maximum lifting speed of 71m / min, the maximum lifting height of 65m. Furthermore, the company also can design extended model its capacity is between the above models according to user requirement.

More

N-TGD Belt

N-GTD belt bucket elevator has characteristics of great conveying capacity/ small size/ low energy consumption/ running stable and reliable/ long service lifetime/ extra high lifting height, it is a new type vertical lifting machine, which is the developed product of introducing similar foreign advanced technology. It can be used for vertical lifting bulk powder materials or small granulated materials. It is widely used for powder or granulated materials with high load lifting system in cement/ chemical / coal/ electricity/ harbor/ food industries. It is specially recommended to use for lifting raw material to preheater in dry-method cement production line/ raw meal to homogenization silo/ cement to cement silo and high load circulating conveying of large ball mill close circuit system, it can completely replace import bucket elevator in same size. So far the maximum lifting capacity of developed product is over 1800m3/h, maximum lifting height is 180m.

More

Large plate chain bucket elevator

Due to the business scale’s continuous expansion of cement manufacturer and energy saving requirements, both at home and abroad using the roller press for raw materials finish grinding and cement combined grinding is more and more, the capacity of single unit has been expanded, making the capacity of conveying equipment matched with the roller press also is increased. Because of the abrasive and lump material, only the plate chain bucket elevator can be used. There are material block/leakage, equipment vibration, motor frequent stop, large back flow and so on, due to unstable material flow out of roller press, abrasive material and process problems, it seriously affect the whole system operating rate. Our company has developed the large plate chain bucket elevator with large lifting capacity based on many years’ experience of designing and manufacturing plate chain bucket elevator. It is suitable for this process system, which makes the process system operating rate to be unaffected because of the plate chain bucket elevator fault.

-

Bulk Material Conveying Chain

More

FU conveyor chain

Fu conveyor chain with high quality alloy steel manufacturing, strict quality management, sophisticated manufacturing technology has long service lifetime. Under normal operation conditions, the lifetime can be up to more than three years.

More

Reclaimer chain

Chain specifications for reclaimer of rectangular material stack and circular material stack as below:

More

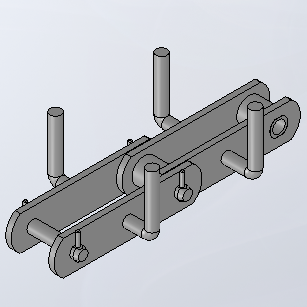

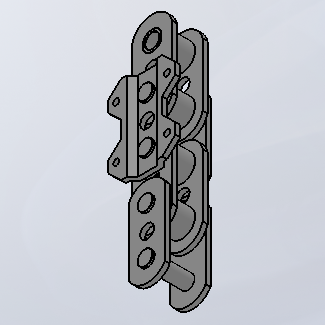

Bucket elevator chain

Plate chain as the core component of the bucket elevator, during chain design our company adopting the plate chain parts "simultaneous failure" design concept, has the lightest weight under the conditions of meeting the chain breaking tension. Each part’s material has been selected high quality alloy steel, developed from German advanced processing and manufacturing process, to ensure that the product is excellent in tensile, wear resistance and service lifetime.

- Technology&Service

-

Spare Parts

More

Bucket

The bucket of elevator, is a key component for material conveying, and also is a kind of wearing part, we have detailedly studied it for many years. We have designed bucket A-type, D-type, L-type with different cross-section shape based on different material and operation condition, under same bucket width there is a maximum bucket volume by optimizing design.

More

Sprocket

The sprocket produced by our company, whether drive or tail of the sprocket, is made of high quality alloy steel as raw materials, by CNC machining centers precision machining sprocket tooth profile and treating tooth surface by induction hardening heat treatment, the surface hardness of the sprocket is HRC54~58, accordingly ensure chain and sprocket tooth correct meshing, to keep bucket elevator running smoothly and extend service lifetime of sprocket.

More

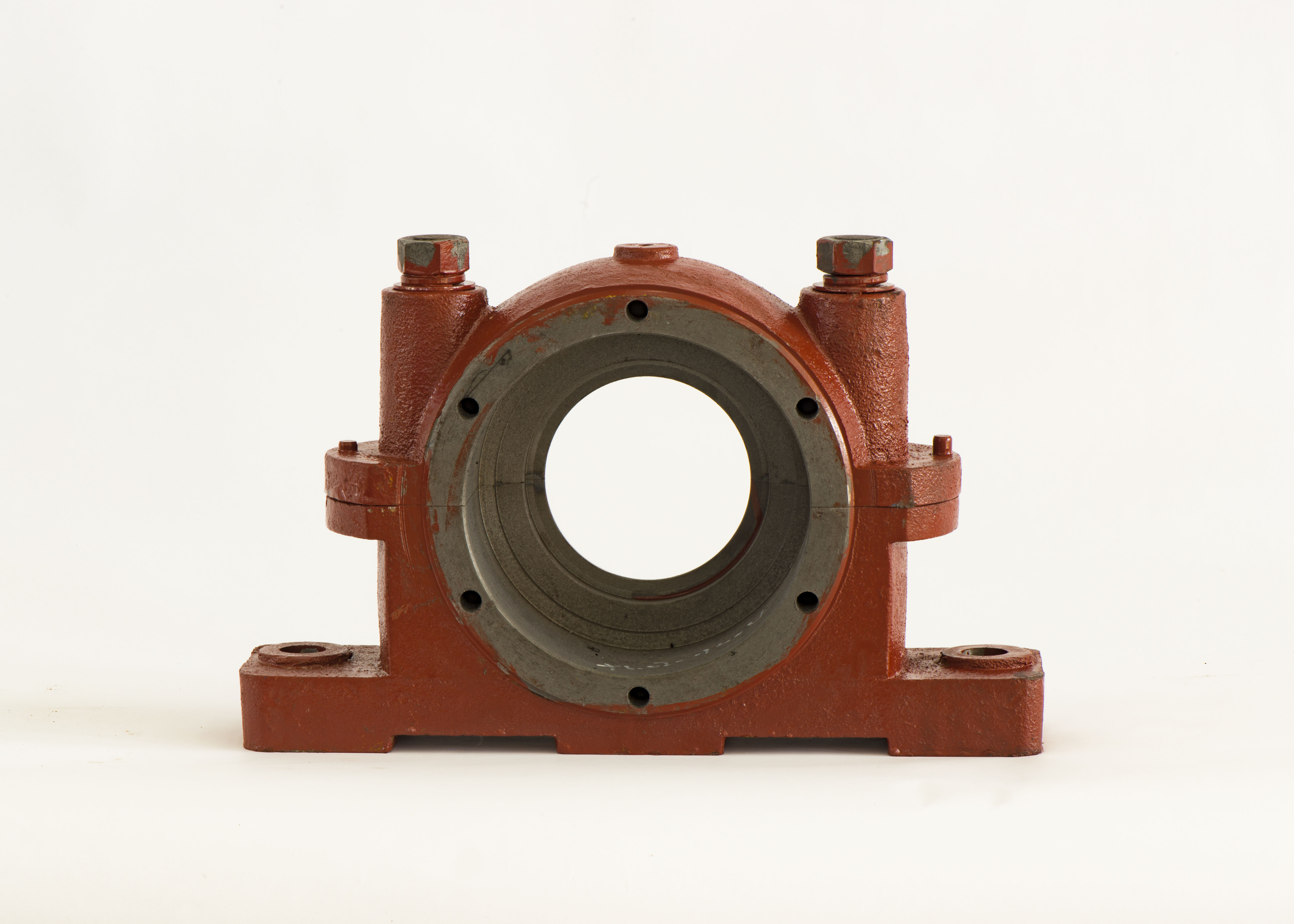

Bearing housing

Including head bearing housing and tail bearing housing.

More

Purchased Components

Gear box,fluid coupling,motor,are famous brands at home and abroad.

- Contact Us

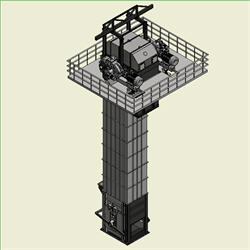

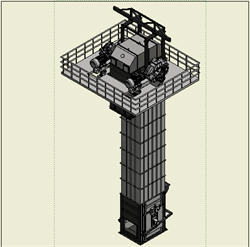

Large plate chain bucket elevator

Due to the business scale’s continuous expansion of cement manufacturer and energy saving requirements, both at home and abroad using the roller press for raw materials finish grinding and cement combined grinding is more and more, the capacity of single unit has been expanded, making the capacity of conveying equipment matched with the roller press also is increased. Because of the abrasive and lump material, only the plate chain bucket elevator can be used. There are material block/leakage, equipment vibration, motor frequent stop, large back flow and so on, due to unstable material flow out of roller press, abrasive material and process problems, it seriously affect the whole system operating rate. Our company has developed the large plate chain bucket elevator with large lifting capacity based on many years’ experience of designing and manufacturing plate chain bucket elevator. It is suitable for this process system, which makes the process system operating rate to be unaffected because of the plate chain bucket elevator fault.

Characteristic

-

Major characteristic

At present, our company has developed capacity of 2500t/h plate chain bucket elevator, and solved the problem of back flow, vibration, tail unit unsteady running, chain out of trail and so on during bucket elevator running, extend service lifetime of the chain, it makes bucket elevator can steady running continuously with the whole system equipment, greatly improving the system operation rate.

1. The plate chain design and processing technology: under satisfying the condition of design chain breaking tension, as far as possible to reduce weight of the chain with chain link plate of lightening hole, where it does not affect the chain breaking tension; by selecting suitable material and matching with the heat treatment process to improve the mechanical properties of materials; at the same time, through reasonable design and processing technology to reduce stress concentration near opening hole of chain parts and improve the chain breaking tension.

2. Drive sprocket device: the drive sprocket device bears all chain and material weight, the load is changed during running, also bear the chain impact load by polygon effect in chain drive, through SolidWorks simulation software and ANSYS finite element analysis software of simulation design and CNC machining center processing suitable tooth profile of drive sprocket, to ensure smooth operation of the machine head device and improve service lifetime of the chain.

3. The tail device: due to instability characteristics of the material feed flow, using wheel with chain out of track mechanism and double tensioning structure with spring tensioning device + gravity tensioning device, which ensure bucket elevator not only safe and stable continuous operation, but also no material leakage.

4. bucket: due to the lifting capacity is too large, in order to reduce equipment size as much as possible, the special bucket cross-section is designed, it has larger volume at the same bucket width, and ensure the discharging angle of material, to match with the chain speed.

The bucket elevator has 6 utility model patents, achieved 2014 annual key areas of equipment manufacturing industry in Zhejiang Province, the first (set) product title.

Through the above key technology development and breakthrough, solve the designing and manufacturing problems, such as bucket elevator feed-back flow, vibration, unsteady running of tail device etc. during operation. Its chain service lifetime is more than three years, the amount of actual using bucket elevator with capacity over 1500t/h is more than 100 sets.

More information please contact us.